Basic Info

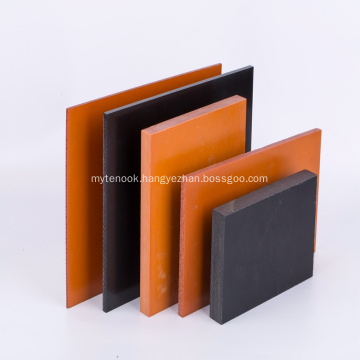

Model No.: HONY-Bakelite

Click on the follow link to find out more information: https://www.honyplastic.com/bakelite-insulation-sheet/

Company Info

- Company Name: Hony Engineering Plastics Limited

- Representative: ZOU SHU YA

- Product/Service: Plastics Sheet , Plastics Rod , CNC Plastic Machined Parts , CNC Metal Machined Parts , Plastics Injection Molding , Antistatic Material

- Capital (Million US $): 200万

- Year Established: 2008

- Total Annual Sales Volume (Million US $): Above US$100 Million

- Export Percentage: 91% - 100%

- Total Annual Purchase Volume (Million US $): Above US$100 Million

- No. of Production Lines: 38

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: 深圳市龙华区大浪街道乌石岗工业区3楼

- Contact Person: Ms. Tina

- Tel: +86-852-34604012

Email to this supplier

Premium Related Products

Other Products

Hot Products

Original Japan SANYO Batteries UR18500f SANYO 18500 1700mAh Battery CellOriginal for Panasonic 18650b 3400mAh Battery/ Panasonic NCR18650b 3400mAh Battery/ 18650 Mod BatteryStock for Samsung 18650 3000mAh 30b 18650 Battery3.7V Sony Vtc4 2100mAh High Drain Rechargeable 18650 Vapor Lithium Ion BatteryAuthentic Cks Dagger 80W Box Mod with Auto Tc100% Original Japan KOH Gen Do Cotton 80PCS in One PackE Cigarette Wire Bracelet Demon Killer Vape Bracelet for VapersNewest Demon Killer Prebuilt Heating Wires 8 in 1 Coil Box KitNew Design Fashion Vape Shoulder Bag for Professional Vapers18650 LG He4 Rechargeable Lithium-Ion Battery 2500mAh/35AWholesale E Cig Heat Sink for 510 Connector Rda Atomizer Vape TankConcave Vape Band Decorative and Protection Mechanical Mod Colors Silicone Vape Band Vaporizer Band Ecig Vape Band510 Drip Tip Disposable Silicone Test Drip Tips E Cigarette Wide Bore Luminous Drip Tips for Atlantis V2 Subtank 2 Mini Sub Tank Nano Plus Arctic AtomizerKuro Koiler Universal Tools 6 in 1 Kits Coil Jig Coiler Winding Coiling Builder Heating Wire Wick Tool for DIY Rda EcigPyrex Glass Tube Replacement Replacable Clear Bell Cap for Glassomizer Vaporizer Aspire Nautilus 5ml Tanks Nautilus Mini 2ml ClearomizerHigh Quality Rx200s Case Ecigarette Leather Case for Wismec Reuleaux Rx200s Mod for Decoration and Protection